Finger shaper / jointer series

-

Indefinite length auto finger jointer

The Indefinite length auto finger jointer is a type of woodworking equipment used to create strong and reliable finger joints in wooden pieces. The machine is designed to handle an indefinite length of wood and can automatically cut and shape the pieces with precision. This saves time and labor costs, allowing manufacturers to produce high-quality finger jointed wooden pieces at a faster rate. The machine can also handle a wide range of wood types and sizes, making it a versatile tool for woodworking manufacturing.

-

MXB3525/MXB3530 Automatic finger shaper for beams

Characteristic:

1.The machine integrates trimming,milling teeth,waste crushing and deburring and other functions into one,trimming,deburring,crushing device and cutting blades are directly fixed to the motor,the cutting position can be adjusted to ensure the verticality of cross-section.

2.The dual high-speed shaft for milling teeth can be adjusted up or down according to actual requirement;the high-speed spindles applies accurate dynamic balance and sealed oil bearings to ensure machining accuracy.

3.Workbench of the manchine adopts imported rails,bearings to make it run smoothly.Rail,bearing has long service life.

4.The timber clamping device,using clamping and pneumatic sensor detection,making it safe and reliable.

5.The workbench is driven by hydraulic cylinder,travel speed can be individually adjusted,the forward speed is adjusted by one-way throttle valva mainly based on cutting amount;the backward includes rapid return and delecration to smooth stop.Additional material supporting device moving with the workbench,the machine has features of high efficiency and low labor intensity.

The MXB3525/MXB3530 Automatic Finger Shaper is a piece of machinery used to shape wooden beams. This machine uses an automated process to accurately shape the fingers in the wood to ensure a precise fit. It is ideal for use in factories or workshops where large quantities of beams need to be processed quickly and accurately. The machine is designed to be user-friendly and efficient, with advanced features such as automated feeding and precise cutting tools. With this machine, the process of shaping wooden beams is streamlined and the production time is significantly reduced.

-

MXB3515 Automatic finger shaper

Characteristic:

Multi-function:trimming,milling,waste,shivering and chip removing.

High-precision shaper spindle,tightness bearings,adjustable working height,all this ensure perfect workpieces.

We have our own factories and have formed a professional production system from material supplying and manufacture to sale, as well as a professional R&D and QC team. We always keep ourselves updated with market trends. We are ready to introduce new technology and service to meet the market needs.

Worktablels move speed is adjustable.

PLC electrical control.

The MXB3515 Automatic finger shaper is a machine used in woodworking to shape and profile wood edges, particularly for finger joints. The finger joints are created by shaping the wood into the required shape with specially designed cutters.The MXB3515 Automatic finger shaper is a modern, fully automatic machine that is designed to increase productivity and accuracy. The machine is equipped with high-speed spindles for efficient cutting and a feed system that automatically adjusts to the thickness of the wood.The operation of the MXB3515 Automatic finger shaper is very straightforward. The wood is fed into the machine and automatically positioned and clamped in place. The machine then shapes the wood into the desired profile using its high-speed cutters. The finished product is then ejected from the machine.Overall, the MXB3515 Automatic finger shaper is a versatile and efficient machine that is widely used in the woodworking industry to shape wood edges for finger joints. It can increase production output while maintaining accuracy, making it a valuable tool for many woodworking operations.

-

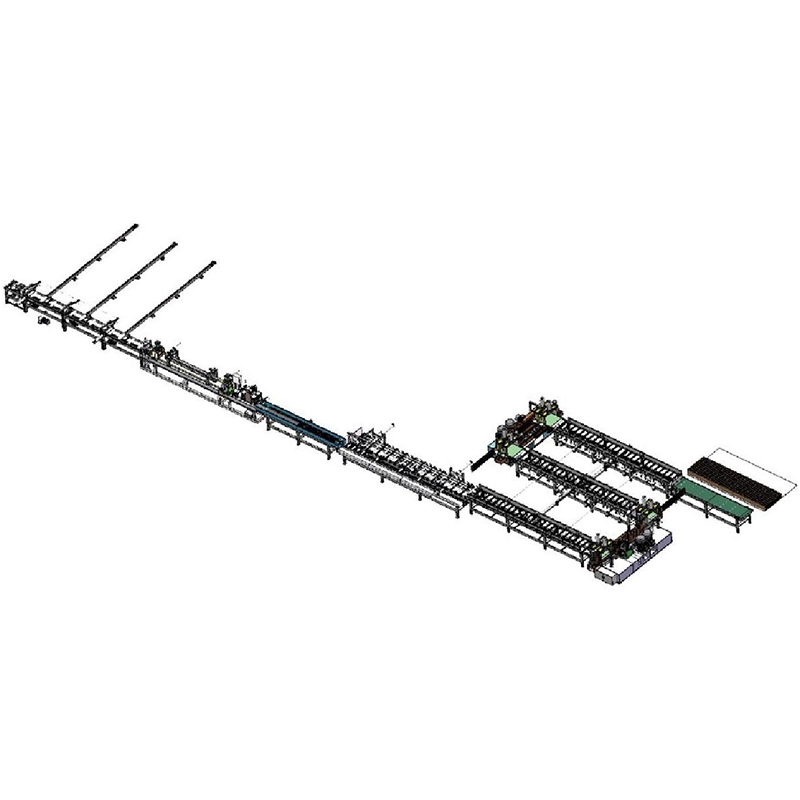

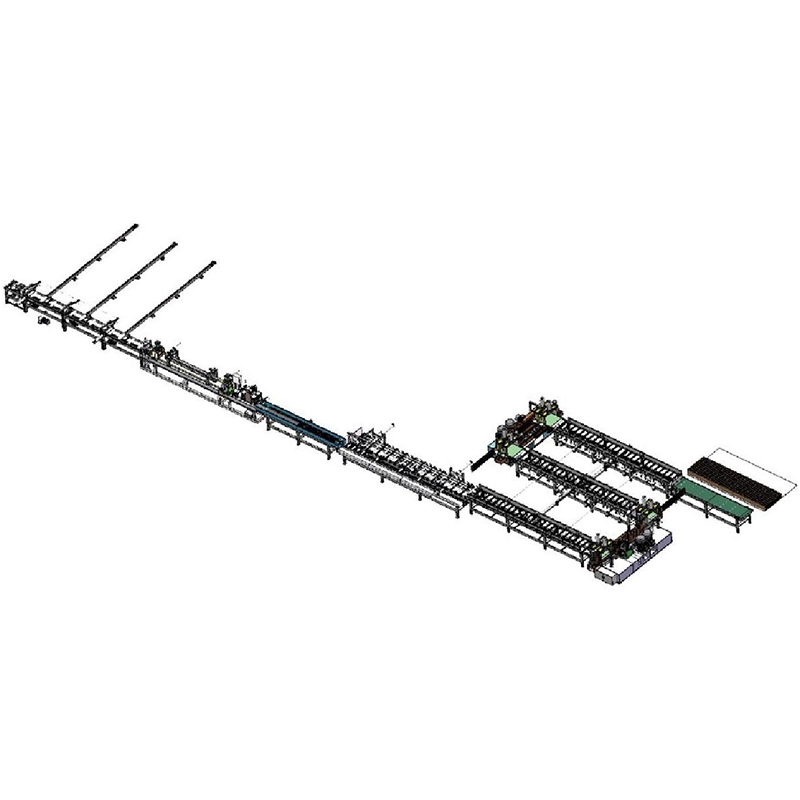

Heavy automatic finger jointer line

A heavy automatic finger jointer line is a type of woodworking equipment used to create a continuous length of lumber from shorter pieces. It uses a combination of hydraulic, electrical and pneumatic systems to quickly and accurately join multiple boards together end-to-end to create a longer piece of lumber. This type of line is commonly used in the manufacturing of furniture, construction materials, and other wood-based products. The jointer also includes high-tech controls to ensure precision cuts and reduce waste.

automatic finger joint line

It insist with two shaper machines and one pressing machine, connect with different conveyors thus no save labor, this line total power 48.4kw, space 24m, need about 2 operators, can make 6-7 pcs 6m wood per minute.We will be dedicated to upgrade of product and technical innovation in the operation philosophy of “First-rate Quality, Sophisticated Technology, High-quality Service”, and strive to bring customer greatest benefit.

Mr. Sun Yuanguang, President and General Manager, together with all staff, expresses our sincere thanks to customers at home and abroad who always give us support and encouragement, and we will march forward and improve quality and technical content of product for making customer satisfied. -

Automatic finger shaper MXB3512 MXB3516

Characteristic:

MXB3515 Automatic finger shaper

Quality assurance.

We have our own brand and attach much significance to quality. The manufacture of running board maintains IATF 16946:2016 Quality Management Standard and monitored by NQA Certification Ltd. in England.

Worktablels move speed is adjustable.

PLC electrical control.

Quality assurance.

The MXB3512 and MXB3516 are two variations of the Automatic Finger Shaper machine used in woodworking to shape and profile wood edges, especially for finger joints. These machines are designed for high-speed cutting, efficiency, and accuracy. They are equipped with a modern feed system that adapts to the thickness of the wood being processed. The MXB3512 and MXB3516 Automatic Finger Shaper machines are easy to use, with a straightforward operation. The wood is fed into the machine, clamped and positioned automatically. The machine then shapes the wood using specialized cutters, producing high-quality finger joints. The finished product is then ejected from the machine, ready for further processing or assembly.Overall, these machines are valuable tools in the woodworking industry because they increase production output while maintaining consistent accuracy. They are versatile and efficient, making them a must-have for many woodworking operations.

-

MHZ1546/1552/1562 Automatic figer jointer series

The MHZ1546/1552/1562 Automatic finger jointer series is a type of woodworking equipment used to create finger joints in wooden pieces. The machine utilizes advanced technology to precisely cut and shape the wood, ensuring a strong and durable joint. This series is designed for high volume production and can handle a wide range of wood types and sizes. The automatic operation makes the process efficient and saves time and labor costs. Overall, the MHZ1546/1552/1562 series is a reliable and essential tool for woodworking manufacturers who need to produce high-quality finger jointed wooden pieces.

-

MHZ1546/1552/1562 Automatic figer jointer series

The MHZ1546/1552/1562 Automatic finger jointer series is a type of woodworking equipment used to create finger joints in wooden pieces. The machine utilizes advanced technology to precisely cut and shape the wood, ensuring a strong and durable joint. This series is designed for high volume production and can handle a wide range of wood types and sizes. The automatic operation makes the process efficient and saves time and labor costs. Overall, the MHZ1546/1552/1562 series is a reliable and essential tool for woodworking manufacturers who need to produce high-quality finger jointed wooden pieces.

-

Automatic finger shaper MXB3512 MXB3516

Characteristic:

MXB3515 Automatic finger shaper

Quality assurance.

We have our own brand and attach much significance to quality. The manufacture of running board maintains IATF 16946:2016 Quality Management Standard and monitored by NQA Certification Ltd. in England.

Worktablels move speed is adjustable.

PLC electrical control.

Quality assurance.

The MXB3512 and MXB3516 are two variations of the Automatic Finger Shaper machine used in woodworking to shape and profile wood edges, especially for finger joints. These machines are designed for high-speed cutting, efficiency, and accuracy. They are equipped with a modern feed system that adapts to the thickness of the wood being processed. The MXB3512 and MXB3516 Automatic Finger Shaper machines are easy to use, with a straightforward operation. The wood is fed into the machine, clamped and positioned automatically. The machine then shapes the wood using specialized cutters, producing high-quality finger joints. The finished product is then ejected from the machine, ready for further processing or assembly.Overall, these machines are valuable tools in the woodworking industry because they increase production output while maintaining consistent accuracy. They are versatile and efficient, making them a must-have for many woodworking operations.

-

Heavy automatic finger jointer line

A heavy automatic finger jointer line is a type of woodworking equipment used to create a continuous length of lumber from shorter pieces. It uses a combination of hydraulic, electrical and pneumatic systems to quickly and accurately join multiple boards together end-to-end to create a longer piece of lumber. This type of line is commonly used in the manufacturing of furniture, construction materials, and other wood-based products. The jointer also includes high-tech controls to ensure precision cuts and reduce waste.

automatic finger joint line

It insist with two shaper machines and one pressing machine, connect with different conveyors thus no save labor, this line total power 48.4kw, space 24m, need about 2 operators, can make 6-7 pcs 6m wood per minute.We will be dedicated to upgrade of product and technical innovation in the operation philosophy of “First-rate Quality, Sophisticated Technology, High-quality Service”, and strive to bring customer greatest benefit.

Mr. Sun Yuanguang, President and General Manager, together with all staff, expresses our sincere thanks to customers at home and abroad who always give us support and encouragement, and we will march forward and improve quality and technical content of product for making customer satisfied. -

MXB3515 Automatic finger shaper

Characteristic:

Multi-function:trimming,milling,waste,shivering and chip removing.

High-precision shaper spindle,tightness bearings,adjustable working height,all this ensure perfect workpieces.

We have our own factories and have formed a professional production system from material supplying and manufacture to sale, as well as a professional R&D and QC team. We always keep ourselves updated with market trends. We are ready to introduce new technology and service to meet the market needs.

Worktablels move speed is adjustable.

PLC electrical control.

The MXB3515 Automatic finger shaper is a machine used in woodworking to shape and profile wood edges, particularly for finger joints. The finger joints are created by shaping the wood into the required shape with specially designed cutters.The MXB3515 Automatic finger shaper is a modern, fully automatic machine that is designed to increase productivity and accuracy. The machine is equipped with high-speed spindles for efficient cutting and a feed system that automatically adjusts to the thickness of the wood.The operation of the MXB3515 Automatic finger shaper is very straightforward. The wood is fed into the machine and automatically positioned and clamped in place. The machine then shapes the wood into the desired profile using its high-speed cutters. The finished product is then ejected from the machine.Overall, the MXB3515 Automatic finger shaper is a versatile and efficient machine that is widely used in the woodworking industry to shape wood edges for finger joints. It can increase production output while maintaining accuracy, making it a valuable tool for many woodworking operations.

-

MXB3525/MXB3530 Automatic finger shaper for beams

Characteristic:

1.The machine integrates trimming,milling teeth,waste crushing and deburring and other functions into one,trimming,deburring,crushing device and cutting blades are directly fixed to the motor,the cutting position can be adjusted to ensure the verticality of cross-section.

2.The dual high-speed shaft for milling teeth can be adjusted up or down according to actual requirement;the high-speed spindles applies accurate dynamic balance and sealed oil bearings to ensure machining accuracy.

3.Workbench of the manchine adopts imported rails,bearings to make it run smoothly.Rail,bearing has long service life.

4.The timber clamping device,using clamping and pneumatic sensor detection,making it safe and reliable.

5.The workbench is driven by hydraulic cylinder,travel speed can be individually adjusted,the forward speed is adjusted by one-way throttle valva mainly based on cutting amount;the backward includes rapid return and delecration to smooth stop.Additional material supporting device moving with the workbench,the machine has features of high efficiency and low labor intensity.

The MXB3525/MXB3530 Automatic Finger Shaper is a piece of machinery used to shape wooden beams. This machine uses an automated process to accurately shape the fingers in the wood to ensure a precise fit. It is ideal for use in factories or workshops where large quantities of beams need to be processed quickly and accurately. The machine is designed to be user-friendly and efficient, with advanced features such as automated feeding and precise cutting tools. With this machine, the process of shaping wooden beams is streamlined and the production time is significantly reduced.

-

Indefinite length auto finger jointer

The Indefinite length auto finger jointer is a type of woodworking equipment used to create strong and reliable finger joints in wooden pieces. The machine is designed to handle an indefinite length of wood and can automatically cut and shape the pieces with precision. This saves time and labor costs, allowing manufacturers to produce high-quality finger jointed wooden pieces at a faster rate. The machine can also handle a wide range of wood types and sizes, making it a versatile tool for woodworking manufacturing.

Phone: +86 18615357957

Phone: +86 18615357957 E-mail: info@hhmg.cn

E-mail: info@hhmg.cn