Hydraulic press series

-

Four-side hydraulic press series(Downward open type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system , which ensure the constant pressure.

■Numerical control and hotkey operation, which reduce human factor and improve quality.

■ 4 workside,high efficiency.

■ Downward open type , which facilitate bigger and longer wood pieces’ loading and unloading.

-

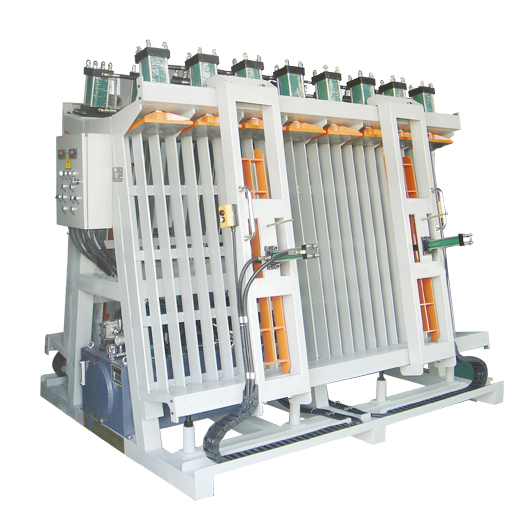

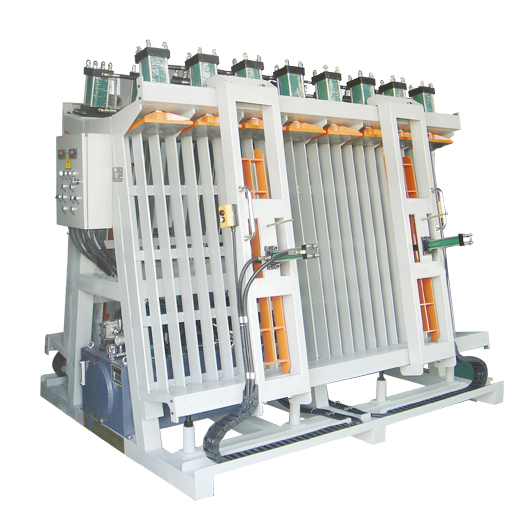

Four-side hydraulic press series (Sectional type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system , which ensure the constant pressure.

■Numerical control and hotkey operation, which reduce human factor and improve quality.

■4 workside,high efficiency.

-

Two-side hydraulic press series (Normal type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing.

What services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency: USD, CNY;

Accepted Payment Type: T/T, Credit Card, L/C,

English, Chinese

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required.And there is pressure-recovery system ,which ensure the constant pressure.

■ Numerical control and hotkey operation, which reduce human factor and improve quality.

There is a wide range of hydraulic press types. All are press machines that work with either fluid or hydraulic pressure. Based on Pascal’s principle, a hydraulic press works because pressure builds up throughout its closed system, exerting equal force within all areas of the container.

-

Single-side hydraulic press series (Normal type)

Single-side hydraulic press series (Normal type)Characteristics:

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness),system pressure can be adjusted according to different pressure required. And there is pressure-recovery system ,which ensure the constant pressure.

How can I get a quotation?

Leave us a message with your purchase requests and we will reply you within one hour on working time. And you may contact us directly by Trade Manager or any other instant chat tools in your convenient.

Hydraulic presses have been around since the late 1700s. They are also called Bramah presses in tribute to inventor Joseph Bramah, a multi-talented man who developed the flush toilet. In fact, studying the motion of fluids when installing toilets helped him create the first hydraulic press.

-

Single-side hydraulic press series(Sectional type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system ,which ensure the constant pressure.

■Sectional type, for shorter wood processing, more flexible and high efficiency.

-

Horizontal hydraulic press glulam press

Characteristic:

1.This machine adopts hydraulic principals characterized by a huge pressure and pressing.

Pressure-supplement system can set the upper and lower limit of pressure and resupply the pressure lost automatically.

2.Top pressure pusher can move in horizontal direction according to working pieces specification.

3.With upward-downward roller on worktop,which facilitate feeding.

4.All operation controlled by buttons and valves,easy to operate.

The horizontal hydraulic press glulam press is a type of machinery used in the manufacturing of glulam beams, which are laminated wood beams used in construction. This press applies hydraulic pressure to wood lamellas to form them into a strong, durable beam. The horizontal design of this press allows for easy loading and unloading of the wood for streamlined production.The press uses a combination of heat and pressure to bond the wood lamellas together using adhesive, resulting in a high-strength beam. After the wood has been pressed and bonded, it is cut to size and shaped based on the project specifications. Glulam beams are known for their strength, versatility, and sustainability, making them a popular choice in modern construction.Overall, the horizontal hydraulic press glulam press plays a vital role in the production of glulam beams, providing an efficient and effective method of manufacturing these important building materials.

-

Flooring press for laminating

Types of Hydraulic Applications

Hydraulic presses come in a wide range of types, suited to specific purposes. Here is an overview of several applications:

Platen presses

The C-frame press is an example of a platen press. All use a ram as well as a solid, and have a surface that is designed with stability in mind. They can be used for banking, drawing, straightening, punching, bending, forming and timing.

Vacuum and laminating presses

Credit cards are made with these presses, which encapsulate several layers of plastic. These presses can also apply film.Stamping presses

These presses are commonly used in the auto and metal working field. They can cut and shape material with a process called deformation with die.

Transfer presses

Used most often in aerospace and the medical industry, these presses mold and stamp rubber.Forging presses

These presses are used strictly on metal. -

Two-side hydraulic press series(Sectional type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system ,which ensure the constant pressure.

■ Numerical control and hotkey operation, which reduce human factor and improve quality

■ Sectional type, for shorter wood processing, more flexible and high efficiency.

-

Four-side hydraulic press series(upward open type)

Performance characteristics:

1.Professional online service team, any mail or message will reply within 24 hours.

High density braced sheeting as back worktop and pressure form the above and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

2.inside thehydraulic system there is pressure -guaranteed and pressure-resupply structure which keep pressure and enhance the quality of products.

3.4 work side,each side with 6 work groups,high efficiency.

4.The front pressure pusher can be moved according to the different working requirements.

5.The machine adopts hydraulic braking system ,hydraulic lock and safety brace by which safety is secured

-

Four-side hydraulic press series(upward open type)

Performance characteristics:

1.Professional online service team, any mail or message will reply within 24 hours.

High density braced sheeting as back worktop and pressure form the above and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

2.inside thehydraulic system there is pressure -guaranteed and pressure-resupply structure which keep pressure and enhance the quality of products.

3.4 work side,each side with 6 work groups,high efficiency.

4.The front pressure pusher can be moved according to the different working requirements.

5.The machine adopts hydraulic braking system ,hydraulic lock and safety brace by which safety is secured

-

Two-side hydraulic press series(Sectional type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system ,which ensure the constant pressure.

■ Numerical control and hotkey operation, which reduce human factor and improve quality

■ Sectional type, for shorter wood processing, more flexible and high efficiency.

-

Flooring press for laminating

Types of Hydraulic Applications

Hydraulic presses come in a wide range of types, suited to specific purposes. Here is an overview of several applications:

Platen presses

The C-frame press is an example of a platen press. All use a ram as well as a solid, and have a surface that is designed with stability in mind. They can be used for banking, drawing, straightening, punching, bending, forming and timing.

Vacuum and laminating presses

Credit cards are made with these presses, which encapsulate several layers of plastic. These presses can also apply film.Stamping presses

These presses are commonly used in the auto and metal working field. They can cut and shape material with a process called deformation with die.

Transfer presses

Used most often in aerospace and the medical industry, these presses mold and stamp rubber.Forging presses

These presses are used strictly on metal. -

Horizontal hydraulic press glulam press

Characteristic:

1.This machine adopts hydraulic principals characterized by a huge pressure and pressing.

Pressure-supplement system can set the upper and lower limit of pressure and resupply the pressure lost automatically.

2.Top pressure pusher can move in horizontal direction according to working pieces specification.

3.With upward-downward roller on worktop,which facilitate feeding.

4.All operation controlled by buttons and valves,easy to operate.

The horizontal hydraulic press glulam press is a type of machinery used in the manufacturing of glulam beams, which are laminated wood beams used in construction. This press applies hydraulic pressure to wood lamellas to form them into a strong, durable beam. The horizontal design of this press allows for easy loading and unloading of the wood for streamlined production.The press uses a combination of heat and pressure to bond the wood lamellas together using adhesive, resulting in a high-strength beam. After the wood has been pressed and bonded, it is cut to size and shaped based on the project specifications. Glulam beams are known for their strength, versatility, and sustainability, making them a popular choice in modern construction.Overall, the horizontal hydraulic press glulam press plays a vital role in the production of glulam beams, providing an efficient and effective method of manufacturing these important building materials.

-

Single-side hydraulic press series(Sectional type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system ,which ensure the constant pressure.

■Sectional type, for shorter wood processing, more flexible and high efficiency.

-

Single-side hydraulic press series (Normal type)

Single-side hydraulic press series (Normal type)Characteristics:

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness),system pressure can be adjusted according to different pressure required. And there is pressure-recovery system ,which ensure the constant pressure.

How can I get a quotation?

Leave us a message with your purchase requests and we will reply you within one hour on working time. And you may contact us directly by Trade Manager or any other instant chat tools in your convenient.

Hydraulic presses have been around since the late 1700s. They are also called Bramah presses in tribute to inventor Joseph Bramah, a multi-talented man who developed the flush toilet. In fact, studying the motion of fluids when installing toilets helped him create the first hydraulic press.

-

Two-side hydraulic press series (Normal type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing.

What services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency: USD, CNY;

Accepted Payment Type: T/T, Credit Card, L/C,

English, Chinese

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required.And there is pressure-recovery system ,which ensure the constant pressure.

■ Numerical control and hotkey operation, which reduce human factor and improve quality.

There is a wide range of hydraulic press types. All are press machines that work with either fluid or hydraulic pressure. Based on Pascal’s principle, a hydraulic press works because pressure builds up throughout its closed system, exerting equal force within all areas of the container.

-

Four-side hydraulic press series (Sectional type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system , which ensure the constant pressure.

■Numerical control and hotkey operation, which reduce human factor and improve quality.

■4 workside,high efficiency.

-

Four-side hydraulic press series(Downward open type)

■ This machine adopts hydraulic principals characterized by a stable motion speed, huge pressure and still pressing. High density braced sheetings as back worktop and pressure from the top and front can prevent the curved angle and make the board glued completely. Low sanding and high output.

■ According to different working specifications(length or thickness), system pressure can be adjusted according to different pressure required. And there is pressure-recovery system , which ensure the constant pressure.

■Numerical control and hotkey operation, which reduce human factor and improve quality.

■ 4 workside,high efficiency.

■ Downward open type , which facilitate bigger and longer wood pieces’ loading and unloading.

Phone: +86 18615357957

Phone: +86 18615357957 E-mail: info@hhmg.cn

E-mail: info@hhmg.cn