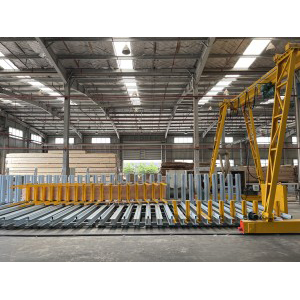

Arched glulam press hydraulic glulam press

1. Technical parameters of 24 meter long straight beam and curved beam

1. The maximum processing size of the straight beam is 24000X1400X600mm (length X width X thickness), the maximum length of the arch curved beam is 24000mm, and the maximum arch height is 3000mm/6000mm.

2. The rated pressure of hydraulic system is 16MPa

3. The maximum force of drawing cylinder is 20 tons.

4. The upper counterweight pressure is 1.5 tons.

(II) Configuration list

1. Host worktables 24500X4000X300 Each

2. Column 67 3. 134 long lashings

4. Universal press foot 67 5. Press foot length 800mm

6. Upper press counterweight iron 2 tons 7. Pull plate mechanism 2 sets of 8. Strip Lock 134pcs 9. Hydraulic station 2 sets of 10. Oil cylinder YGB125X250 2pcs 11. Control box 2 sets of 12. Gantry crane (span 5 meters /9 meters)2 sets 13 gantry guide rails 2, 26 meters.

2. Technical parameters of 18 meter long straight beam and curved beam

The maximum processing size of the straight beam is 18000X1400X600mm (length X width X thickness), the maximum length of the arched curved beam is 18000mm, and the maximum arch height is 3000mm/4500mm.

The rated pressure of hydraulic system is 16MPa

Maximum pulling force of oil cylinder is 20 tons.

4 Upper weight pressure 1.5 tons.

(II) Configuration list

1. Host workbench 18500X4000X300 One

2. Column 50 3. Long pull 100 pieces

4 Universal presser foot 50pcs 5. Press foot length 800mm

6. Upper press counterweight iron 2 tons 7. Pull plate mechanism 2 sets of 8. Pull Strip Lock 100pcs 9. Hydraulic station 2 sets of 10. Oil cylinder YGB125X250 2pcs 11. Control box 2 sets of 12. Gantry crane (span 5 meters /7 meters)2 sets 13 gantry guide rails 2, 20 meters.

3. Technical parameters of 12-meter-long straight beam and curved beam

The maximum processing size of straight beam is 12000X1400X600mm (length X width X thickness), the maximum length of arched curved beam is 12000mm, and the maximum arch height is 3000mm/4500mm.

The rated pressure of hydraulic system is 16MPa

Maximum pulling force of oil cylinder is 20 tons.

4 Upper weight pressure 1.5 tons.

(II) Configuration list

1. Host workbench 12500X4000X300 One

2. 33 columns 3. Long strip 66 pieces

4 universal press foot 33 5. Press foot length 800mm

6. Upper press counterweight iron 2 tons 7. Pull plate mechanism 2 sets of 8. Strip Lock 66pcs 9. Hydraulic station 2 sets of 10. Oil cylinder YGB125X250 2pcs 11. Control box 2 sets of 12. Gantry crane (span 5 meters /7 meters)2 sets 13. Gantry guide rail 2, 14 meters.

4. Technical parameters of 6-meter-long straight beam and curved beam

The maximum processing size of straightening beam is 6000X1400X600mm (length X width X thickness), the maximum length of arched curved beam is 6000mm, and the maximum arch height is 3000mm.

The rated pressure of hydraulic system is 16MPa

Maximum pulling force of oil cylinder is 20 tons.

4 Upper weight pressure 1.5 tons.

(II) Configuration list

1. Host workbench 6500X4000X300 One

2. 16 columns 3. Long pull strips 32 pieces

4 universal press foot 16 5. Press foot length 800mm

6. Upper press counterweight iron 2 tons 7. Pull plate mechanism 1 set of 8. Strip Lock 32pcs 9. Hydraulic station 1 set of 10. Oil Cylinder YGB125X250 1pcs 11. Control box 1 set of 12. Gantry crane (span 5 meters)1 set of 13. Gantry guide rail 2, 8 meters.